- #VECTRIC FORUM CARVING MULTILAYER PLASTIC HOW TO#

- #VECTRIC FORUM CARVING MULTILAYER PLASTIC UPGRADE#

- #VECTRIC FORUM CARVING MULTILAYER PLASTIC FULL#

- #VECTRIC FORUM CARVING MULTILAYER PLASTIC PRO#

- #VECTRIC FORUM CARVING MULTILAYER PLASTIC PROFESSIONAL#

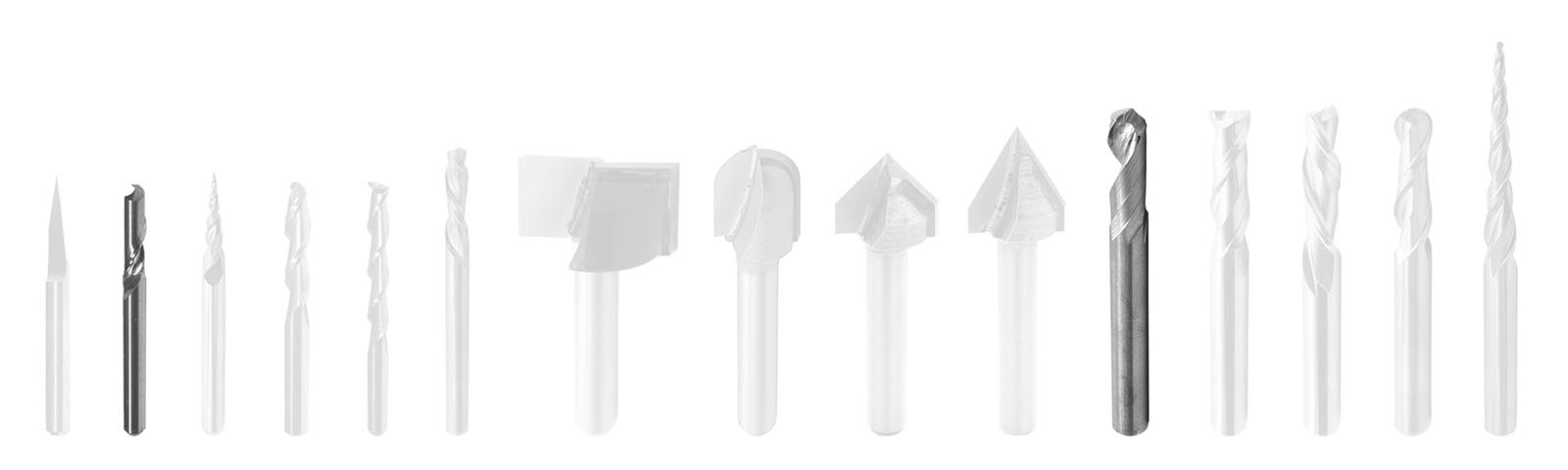

Any type of blade may be used, even to a jeweler's slotting saw, or at the other extreme, a rip-saw blade, but be sure to mount it BACKWARDS before trying to do any free-hand carving with it.Įlectric Hand-Grinders The small high-speed electric hand-grinders on the market see Plates 2A and 2B are perhaps the handiest and most popular of light-weight equipment for free-hand carving, since there is such a large variety of cutters, points and other accessories available to fit them. This makes it safe, so that it will not grab the work out of your hands or cut your hands, yet there is still sufficient angle in the teeth to do a good carving job, although the large diameter of the blade makes it impossible to make sharp turns or to do certain types of work. The next type of carving cutter in point of simplicity and low cost is a circular saw-blade, mounted BACKWARDS. Even if you have complete carving equipment, you need one coarse wheel for rough-shaping, as these work very fast and handle larger surfaces than the cutters. It is possible to obtain these in various shapes and thicknesses, or their shapes can be altered by using a wheel-dresser, or another piece of stone from a broken wheel, so that rounded or pointed shapes can be obtained for finer work. Any type or shape of wheel, travelling at fairly high speed and not too fine a grain may be used. The simplest is a coarse grinding-wheel, of any shape, mounted in a grinding-head, or on an arbor in a lathe or drill-press.

#VECTRIC FORUM CARVING MULTILAYER PLASTIC PROFESSIONAL#

The cutting edges are blunt and practically square, and you can hold your fingers against them (without pressure) while revolving, without damage.Įquipment for power-carving runs the entire gamut from the crudest home-made contraptions to the most expensive professional carving-spindles, and various types will be described. Moreover, the use of power tools for carving in this material is safe, as compared with carving in other materials, for the reason that the cutters will not "grab" at your fingers and knuckles as wood-carving cutters do, since they do not have the "rake" or pointed edge. Even with a crude power setup and home-made cutters, the effects gained are entirely satisfactory, even if not quite so fast.

Given the proper type of cutter, and sufficient power, the material practically ' melts away" when presented to the cutter, and you feel as if you were working in soft modelling clay.

#VECTRIC FORUM CARVING MULTILAYER PLASTIC UPGRADE#

I think it will do a ton of what I need in the here-and-now and was easy as pie to get going with so I figured I would upgrade down the line if it turns out that I need more. I'm sure I will find other things I need/want as I get deeper into it.įYI: I have purchased Cut2D. As for helical drilling I did not see that mentioned in either. In a lot of cases I don't need a real great surface but sometimes it's required so maybe the work around is fine.

#VECTRIC FORUM CARVING MULTILAYER PLASTIC FULL#

I can make Cut2D do this by drawing a slightly smaller pocket shape inside the true outline and then use that as the vector for the roughing and run a profile pass on the real outline full depth climb cutting to get the desired action but that's tediuous. I would also like to be able to specify pocket with an offset/raster layered roughing cut and then a final full depth light finishing pass. The big things I want are helical interpolation for boring and drilling with an end mill vs offset layered pocketing.

#VECTRIC FORUM CARVING MULTILAYER PLASTIC HOW TO#

Thanks for the pointers and I did look at those pages actually but I was still not clear if some of the features I would be interested in were there in V-Carve or if even I was missing how to do them in Cut-2D. I hope this helps and please let me know if you have any additional questions.

#VECTRIC FORUM CARVING MULTILAYER PLASTIC PRO#

There's a link on the bottom of the Cut2D Overview page that provides more details about the additional functionality in VCarve Pro.ĭifferences between Cut2D and VCarve Pro > Not much detail beyond that.Hello Photomankc, All I saw in the comparison page was Basic 2D in Cut2D and Basic + Advanced 2D in VCarve. I was wondering if anyone can lay out what the main advantages of VCarve over Cut2D are for a person making 2.5D parts far more often than signs or engravings. My intended use is mainly to support a robotics hobby to deprive me of the remainder of my cash supply. Probably plenty of other stuff I don't know about yet. Any way lead-in other than the zig-zag/straight plunge.

There are some things missing, or at least that I don't see right away. I'm pretty well convinced that Cut2D is going to work for 80% of what I need to do just playing around with it.

0 kommentar(er)

0 kommentar(er)